Composites are the most important

materials to be adapted for aviation since the use of aluminium in the

1920s. Composites are materials that are combinations of two or more

organic or inorganic components. One material serves as a "matrix," which

is the material that holds everything together, while the other material

serves as a reinforcement, in the form of fibres embedded in the matrix.

Until recently, the most common matrix materials were "thermosetting"

materials such as epoxy, bismaleimide, or polyimide. The reinforcing

materials can be glass fibre, boron fibre, carbon fibre, or other more

exotic mixtures.

Fiberglas is the most common composite

material, and consists of glass fibres embedded in a resin matrix.

Fiberglas was first used widely in the 1950s for boats and automobiles,

and today most cars have fibreglass bumpers covering a steel frame.

Fiberglas was first used in the Boeing 707 passenger jet in the 1950s,

where it comprised about two percent of the structure. By the 1960s, other

composite materials became available, in particular boron fibre and

graphite, embedded in epoxy resins. The U.S. Air Force and U.S. Navy began

research into using these materials for aircraft control surfaces like

ailerons and rudders. The first major military production use of boron

fiber was for the horizontal stabilizers on the Navy's F-14 Tomcat

interceptor. By 1981, the British Aerospace-McDonnell Douglas AV-8B

Harrier flew with over 25 percent of its structure made of composite

materials.

Making composite structures is more

complex than manufacturing most metal structures. To make a composite

structure, the composite material, in tape or fabric form, is laid out and

put in a mould under heat and pressure. The resin matrix material flows and

when the heat is removed, it solidifies. It can be formed into various

shapes. In some cases, the fibres are wound tightly to increase strength.

One useful feature of composites is that they can be layered, with the

fibres in each layer running in a different direction. This allows

materials engineers to design structures that behave in certain ways. For

instance, they can design a structure that will bend in one direction, but

not another. The designers of the Grumman X-29 experimental plane used

this attribute of composite materials to design forward-swept wings that

did not bend up at the tips like metal wings of the same shape would have

bent in flight.

The greatest value of composite

materials is that they can be both lightweight and strong. The heavier an

aircraft weighs, the more fuel it burns, so reducing weight is important

to aeronautical engineers.

Despite their strength and low weight,

composites have not been a miracle solution for aircraft structures.

Composites are hard to inspect for flaws. Some of them absorb moisture.

Most importantly, they can be expensive, primarily because they are labour

intensive and often require complex and expensive fabrication machines.

Aluminium, by contrast, is easy to manufacture and repair. Anyone who has

ever gotten into a minor car accident has learned that dented metal can be

hammered back into shape, but a crunched fibreglass bumper has to be

completely replaced. The same is true for many composite materials used in

aviation.

Modern airliners use significant amounts

of composites to achieve lighter weight. About ten percent of the

structural weight of the Boeing 777, for instance, is composite material.

Modern military aircraft, such as the F-22, use composites for at least a

third of their structures, and some experts have predicted that future

military aircraft will be more than two-thirds composite materials. But

for now, military aircraft use substantially greater percentages of

composite materials than commercial passenger aircraft primarily because

of the different ways that commercial and military aircraft are

maintained.

Aluminium is a very tolerant material and

can take a great deal of punishment before it fails. It can be dented or

punctured and still hold together. Composites are not like this. If they

are damaged, they require immediate repair, which is difficult and

expensive. An airplane made entirely from aluminium can be repaired almost

anywhere. This is not the case for composite materials, particularly as

they use different and more exotic materials. Because of this, composites

will probably always be used more in military aircraft, which are

constantly being maintained, than in commercial aircraft, which have to

require less maintenance.

Thermoplastics are a relatively new

material that is replacing thermosets as the matrix material for

composites. They hold much promise for aviation applications. One of their

big advantages is that they are easy to produce. They are also more

durable and tougher than thermosets, particularly for light impacts, such

as when a wrench dropped on a wing accidentally. The wrench could easily

crack a thermoset material but would bounce off a thermoplastic composite

material.

In addition to composites, other

advanced materials are under development for aviation. During the 1980s,

many aircraft designers became enthusiastic about ceramics, which seemed

particularly promising for lightweight jet engines, because they could

tolerate hotter temperatures than conventional metals. But their

brittleness and difficulty to manufacture were major drawbacks, and

research on ceramics for many aviation applications decreased by the

1990s.

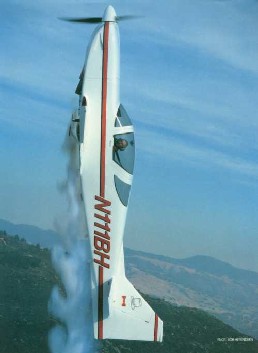

many modern light aircraft are constructed in composite

material such as this Glasair

Aluminium still remains a remarkably

useful material for aircraft structures and metallurgists have worked hard

to develop better aluminium alloys (a mixture of aluminium and other

materials). In particular, aluminium-lithium is the most successful of

these alloys. It is approximately ten percent lighter than standard

aluminium. Beginning in the later 1990s it was used for the Space Shuttle's

large External Tank in order to reduce weight and enable the shuttle to

carry more payload. Its adoption by commercial aircraft manufacturers has

been slower, however, due to the expense of lithium and the greater

difficulty of using aluminium-lithium (in particular, it requires much care

during welding). But it is likely that aluminium-lithium will eventually

become a widely used material for both commercial and military aircraft.