|

The Northrop Flying Wing

and the B2 bomber

A design as aeronautically clean as the Flying Wing

has a big advantage over conventional aircraft design. This

advantage is that drag has been reduced to a minimum. And as a

result of this minimum drag, the performance of the Flying Wing is

unequalled in speed, range and operating economy.

For many years airplane designers have realized that by reducing

drag -- the drag caused by the shape or form of an aircraft -- its

performance could be greatly increased. Early steps in this

direction were changes from biplane to monoplane design; the

elimination of external wing struts and flying wires; and the

incorporation of retractable landing gears. However, in spite of

all these advancements, the average conventional airplane of today

still has two to four times the drag of a flying wing. So in order

to reduce drag to its absolute minimum, aircraft designers took

the drastic step of eliminating the fuselage and tail and putting

the pilot, the power plant and payload in the wing envelope.

The chief exponent of Flying Wing design in the United States was

John K. Northrop. John Northrop was born in Newark, New Jersey in

1895. When he was nine years old his family moved to Santa

Barbara, California. His great interest in mechanics curtailed his

formal education, and, after brief periods as garage mechanic,

carpenter and draftsman, he went to work in 1916 for the Loughead

Brothers, who were then engaged in building twin-engine flying

boats in Santa Barbara. Except for a stint with the Army Signal

Corps during World War I, Northrop stayed with the Lougheads until

1923. In that year, he joined the Douglas Aircraft Company, which

was then preparing the famous Around-the-World Cruisers. He stayed

for four years working as draftsman, designer and project engineer

on many early Douglas planes.

In January, 1927, John Northrop and three other men

formed the Lockheed Aircraft Company. It was at this time that he

designed the famous Lockheed Vega — a high wing, cantilever

monocoque airplane which was far ahead of its time in design. It

was widely used by many of the top flyers such as Amelia Earheart,

G. Hubert Wilkins, Frank Hawks, and the noted Wiley Post. Many

speed records were set by the Lockheed Vega aircraft.

In the summer of 1928, John Northrop began his research of flying

wing aircraft. He formed a small engineering group known as the

Avion Company. He built and test flew one of the first 2mi-flying

wing aircraft in the country. Although it did carry the pilot and

engine power plant in the wing, it was not a true flying wing

because of its small tail carried on twin booms. This plane made

numerous flights in 1929 and 1930 and recorded much valuable

research data. Unfortunately, the depression of the early 1930’s

caused further research to be abandoned.

As years passed and further advancements were made,

John Northrop became recognized as the genius behind the Flying

Wing design and the leading exponent of flying wing design in the

United States. In Germany the flying-wing-design concept

advantages were also shared by Alexander Lippisch and the Horton

Brothers and in England by Hill. All were designers, who built and

flew successful Flying Wing aircraft. Because it had no fuselage,

even the Wright Bi-plane can be considered in this category in

spite of its multiplicity of wing struts and wires. The Wrights’s

plane carried the power plant and pilot directly on the wing

system and was controlled longitudinally by a front elevator which

was, in fact, a lifting wing surface.

In 1923 John Northrop became interested in the flying wing design

after a discussion with Tony Stadlman, who had worked with

Northrop in 1917 at the Lockheed factory, then located in Santa

Barbara. Stadlman was plant manager of the Douglas Company in Los

Angeles at this time and young Northrop was an engineer. Stadlman

believed the ideal aircraft of the future was in the true “flying

wing” design. From that day on John Northrop’s goal was to design

and perfect the Flying Wing.

During the early stages of design development, Northrop held

discussions with the late Dr. Theodore von Karman of the

California Institute of Technology. Northrop later hired Karman’s

assistant, Dr. William Sears, to become his Chief Aerodynamicist.

Walt Cerny, who came to work for Northrop in 1929, was made

assistant Chief of Design. These men had direct supervision of the

Flying Wing from its inception. The encouragement and assistance

of these men, plus the enthusiastic collaboration of the many

Northrop employees, enabled this amazing design to become a

reality.

The pressure of designing and building conventional aircraft

prevented complete concentration on the solution of the Flying

Wing design, and it was not until later that they were able to

focus their efforts on Northrop’s dream of a true flying wing.

Northrop’s first semi-flying wing plane was flown in 1928. It did

make use of external control surfaces and carried outrigger twin

booms -- quite a radical aircraft for its time. The fuselage was

completely eliminated, and the pilot was housed in the wing along

with the power plant.

The big problem overcome in designing the flying

wing revolved around the buried engine concept. The entire engine

propeller shaft had to be buried within the wing foil. This

increased the problems of cooling the engine and of turning the

long drive shaft to the propellers.

The dimensions of the first Northrop semi-flying wing were: It had

a wing span of 30 feet, 6 inches, its length was 20 feet, and its

overall height was five feet. Wing area was 184 square feet and

aspect ratio was 5.12 to 1. Landing gear was of the tricycle type

with the main wheels forward and a tread of 9 feet between the

main wheels. Power was supplied by a single four-cylinder 90

horsepower Menasco engine for the tractor powered version. This

aircraft later was powered by a Cirrus Engine when it was rebuilt

as a pusher-design aircraft.

N1M “Jeep”

In July, 1939, John Northrop began engineering tests for a new

flying wing design. This design was known as the N1M “Jeep”. The

first flight tests were conducted at Muroc Dry Lake in July 1940.

Test pilot for the first flight was Vance Breese. Early tests

showed the plane to be satisfactory in stability and control.

Shortly thereafter, the flight test program was turned over to Mr.

Moye W. Stephens, Northrop Test Pilot and Secretary to the

Northrop Corporation. During 1940 and 1941, over 200 flights were

made in this aircraft to gather further data. Control of the

aircraft was achieved through the use of a system of elevons and

wing tip rudders. The elevons served in tailless type aircraft

both as elevators and ailerons. Rudder action was provided by

control surfaces incorporated in the drooping wing tips.

This wing had a wing span of 38 feet and a length of 17 feet, an

overall height of 5 feet, a wing area of 300 square feet, and an

aspect ratio was 4.75 to 1. It, too, had a tricycle landing gear.

It originally carried two four-cylinder Lycoming engines of 65

horsepower each, which were later replaced by two six-cylinder

Franklin air-cooled engines of 120 horsepower each. The drooping

wing tips of the N1M were later eliminated.

The Ni M “Jeep” was truly the first American flying

wing aircraft. Today it resides in the National Air and Space

Museum Storage facility at Silver Hill, Maryland, a short distance

outside of Washington, D. C. It is hoped that this aircraft is one

that will be displayed in the new Air and Space Building when it

is completed on the Mall in Washington, D.C.

XB-35 Flying Wing

The XB-35 was the first in a series of large Flying

Wing Bombers. It was a bombardment type aircraft of exceptionally

long range and heavy load capacity. Two XB-35 and 13 YB-35’s were

initially scheduled to be built under Army contracts. But only six

of the big wing bombers were completed and test flown. The XB-35

had a wing span of 172 feet and a wing area of 4,000 square feet.

It was capable of operating under overloading conditions at a

gross weight of 209,000 pounds or 104.5 tons.

Prior to the XB-35 design, Northrop had flown twelve tailless

aircraft designs since the company was founded. Northrop engineers

learned much about these experimental models and had made hundreds

of additional models for wing tunnel tests. For the first time in

the history of military aeronautics, the flying wing contributed

many advancements to military design in the bombardment category.

Five of the leading advantages were:

1. The low drag, high lift feature of the Flying Wing meant that

in practice the XB-35 could transport any weight faster, farther

and cheaper than an aircraft of conventional design.

2. The simplicity of construction of the XB-35 Flying Wing

presented few structural complications. It cost less to build

since it was built as a single unit in which the structure

extended through from tip to tip with no added tail or fuselage to

build.

3. It had better weight distribution. Compartments along the span

could distribute the bomb load and weight more evenly over the

wing surface which supported it. This also would have applied to

cargo if a cargo version had been built. It eliminates the need

for excessive structural weight such as is necessary in

conventional bombers where the weight is concentrated in the

fuselage and must be distributed over the wing from this point

through the use of heavy structural members.

4. For ease in loading and unloading, cargo could be placed in

span wise compartments where any part of the plane’s load was

easily accessible through its own cargo or bomb bay doors. This

provided direct access to all portions of the cargo.

5. The XB-35 for military purposes presented a smaller target

while engaged in either offensive or defensive operations.

Comparisons between the Flying Wing and conventional aircraft is

also illustrated by performance figures obtained from Northrop and

backed by many years of research tests in which planes identical

in scale to the XB-35 were used. The XB-35 was built to be 20

percent faster than conventional bomber aircraft with identical

loads and horsepower. Normal crew for the XB-35 was nine men --a

pilot, co-pilot, bombardier, navigator, engineer, radio operator,

and three gunners.

Cabin space was available for six more crew

members, who could substitute on long-range missions. Folding

bunks were built in the XB-35 to accommodate the off-duty crewmen.

These fifteen men were housed entirely within the wing foil

itself. The XB-35 was built of a new aluminium developed by

the Alcoa Company. Tests showed this material to be considerably

stronger than previous metals used. Gasoline was carried in bullet

proof, leak proof fuel cells within the wing of the XB-35 and

additional range was built in by the addition of additional fuel

tanks in the bomb bay and other wing compartment areas. The wing

section of the XB-35 was 37-1/2 feet long at the centre,

tapering to slightly more than nine feet at the wing tips. It

swept back from centre to tips making the overall length of the

ship slightly more than 53 feet. The XB-35 stood over 20 feet tall

when at rest on its tricycle landing gear. It was equipped with

5’6” dual wheels on the main gear and a 4’8” wheel on the nose

gear.

The XB-35 received its initial start from the Army Air Corps in

September, 1941, following a visit by Assistant Secretary of War

Robert Leavitt, General H. H. Arnold, and Major General Oliver P.

Echols. At this time, Northrop submitted a preliminary design for

the XB-35 to Wright Field. Army officials were more than satisfied

because they awarded a contract for the altitude performance with

a pressurized cabin for the crew and a more than adequate bomb

load. There would not have been an XB-35 Flying Wing Bomber had it

not been for the enthusiasm and foresightedness of men like John

Northrop, General Arnold, General Echols, and Mr. Leavitt.

In November, 1941, two XB-35 prototypes were ordered by the Army

Air Force. Preliminary design work began on the XB-35 early in

1942, and on July 5th of that year the mock-up Board from Wright

Field inspected a full size wood mock-up of the centre section and

a portion of the left wing. Official approval was given. Northrop

built a new bomber plant at the end of the company’s grounds in

Hawthorne, California. This plant was completed in January, 1943

and fabrication of the parts for the first XB35 were begun. The

complexities of design in building the B-35 represented an

operation of major size. The Martin Company played a very

important role by providing wind tunnel and other research data

for the XB-35 design. To provide flight test data, Northrop built

four, sixty foot wing span N9M Flying Wings. While the XB-35 was

taking shape in the Hawthorne factory, thousands of test flights

were run on the N9Ms to gather data which could be worked into the

XB-35 design. This time-saving device enabled Northrop engineers

to cut development time from the XB-35. Over the next three years

flight tests were conducted at Muroc Army Air Base to gather data

while the XB- 35 was taking shape.

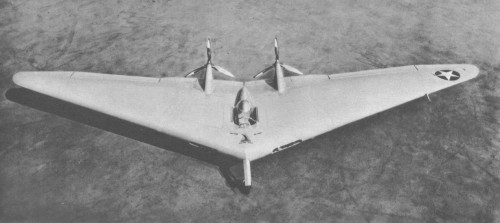

A X8-35 is shown in flight over Muroc Dry

Lake.

Eight four-bladed counter rotation propellers drove the Flying

Wing through the air.

This view clearly shows the turret blisters on the upper portion

of the wing envelope.

The XB-35 used elevons which were

installed on the trailing edges with landing flaps, trim flaps and

rudders. The elevon was a Northrop invention in which the function

of both elevators and ailerons were combined. Further control was

achieved by wing slots. The XB-35 was first flight tested during

the summer of 1946 by Northrop’s Chief Pilot, Max Stanley. One

YB-35 was slated to be turned over the the Navy and was to be

designated XB2T-1; however, this did not take place. The Navy was

to have flown and tested the aircraft for research purposes, but

this project was cancelled.

After the prototype XB-35 models were built at the Hawthorne

plant, a war time plan was begun to build 200 B-35 Flying Wing

bombers by Martin Aircraft Corporation at Omaha, Nebraska. Martin

had previously built B-29 bombers, and it was expected that these

would be phased out - in favour of the B-35 Flying Wing

Bombers. This program was dropped, however, with the conclusion of

World War II. The first XB-35 flew on June 25, 1946. The power

plants of the XB-35 were Pratt-Whitney “Wasp Major” engines. It

had two B-4360-17 and two R-4360-21 engines of 3,000 horsepower

each with double turbo super chargers and eight coaxial counter

rotating - four bladed Hamilton Standard pusher propellers. Tests

were also run on three-bladed propellers, but the four- bladed

models proved to be the most efficient. The aircraft was designed

so that other types of engines could be adapted as they were made

available.

The XB-35 was to have carried twenty 50

calibre machine guns, but these were not installed on the number

one prototype XB-35. Seven remote-control gun turrets were aimed

from central firing sighting stations behind the pilot and on top

of the cone protruding from the trailing edge. Four gun turrets

were fitted above and below the centre section. Two gun turrets

were visible outboard of the engines -- one on top and one below.

Four guns were to have been placed in the tail cone. The first two

XB-35 and sole YB-35 Flying Wings had “Wasp Major” engines. But on

June 1, 1945, orders were issued to have the next two finished

with Allison J-35-A-5 jet engines. These models were known as

YB-49 jet Flying Wing Bombers. On June 25, 1945, American Aviation

took a bold step into the future. On this date the world’s first

all Flying Wing Bomber took to the air from Northrop Field at

Hawthorne, California. The crew for this first flight were pilot,

Max Stanley and Dale Schroeder, flight engineer.

Following the flight of the first XB-35, (SIN

42-13603), a second prototype XB-35 first flew in November of

1946. The second prototype XB-35, (S/N 42-38323) soon joined her

sister ship on the ramp at Muroc Army Air Base. When the XB-35 was

completed and had made its maiden flight, further tests were

conducted to prove the feasibility of the design. The two

Pratt-Whitney R-4360-21 Wasp Major engines drove the inboard

contra-rotating propellers and the two R-4360-17’s turned the

outer pair of propellers. Each engine developed 3,000 horsepower.

The metal housing over the propeller shafts offered enough area to

counter-act any yawing tendency of the Flying Wing design, and

counter rotating propellers gave additional stability by

eliminating torque problems. Cooling air for the radial engines

were ducted from openings in the leading edge of the wing. The

XB-35 had a maximum speed of 395 miles per hour and a cruising

speed of 183 miles per hour.

this is a rare photo of nine

Northrop Flying Wing Bombers.

Many people do not realize that more than one or two prototypes

were built of this design.

Here, for the first time, is actual proof of their existence.

Two of the big wing bombers are undergoing modifications from

XB-35’s to Flying Wing B-49 1t Bombers.

The entire project was later cancelled by the Air Force.

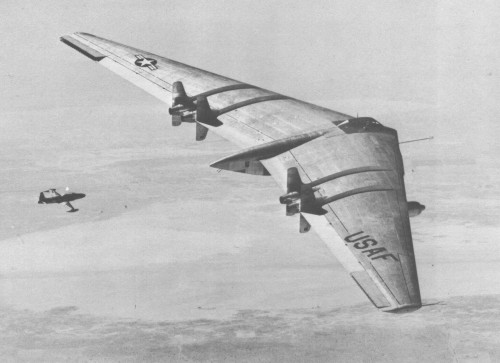

YB-49 and YRB-49A

With the introduction of the YB-49 to flight status in the fall of

1947, it was anticipated that this model would prove to be the

most successful flying wing aircraft. A contract ordering the

conversion of two YB-35 Flying Wings was issued on June 1, 1945.

This specification called for the installation of eight Allison

J-35-A-5 turbo jet engines of 4,000 pounds thrust each. The

YB-49 Flying Wing weighted 88,100 pounds when it was rolled out of

the factory. The normal loaded weight was 205,000 pounds. This

could be boosted to 213,000 pounds if necessary. The first flight

was made on the number one prototype YB-49 on October 1, 1947.

This aircraft, S/N 42-102367, was successfully flown from

Hawthorne, California to Muroc Air Force Base by Northrop’s Chief

Test Pilot, Max Stanley. Subsequent test flights pushed the plane

to a top speed of 520 miles per hour and placed the ceiling

surface at 42,000 feet. It held fuel capacity of 17,545 gallons

and had a range of 4,450 miles. The YB-49 Flying Wing jet bomber

was capable of carrying over 36,760 pounds of bombs for a distance

of 1,150 miles. A normal 10,000 pound load could be carried for an

estimated 4,000 miles on 6,700 gallons of fuel. This was less than

half the range of the B-35. This was due to the great quantity of

fuel required by the turbo jet engines; however, a 100 mile

increase in speed was gained in the YB-49.

Over twenty months of research and flight testing was conducted on

the two YB-49 prototypes at Muroc Air Field. During this time,

payload tests and endurance records were broken. Contracts were

placed for thirty RB-49’s and for converting the remaining ten

B-35 airframes to YRB-49A strategic reconnaissance type aircraft.

During two years of flight testing, stability problems encountered

in the YB-49 design had not been overcome and further tests were

planned. A new autopilot was to be designed and built into the

aircraft. Before this could be done, the first prototype crashed:

On the morning of June 5, 1947, Captain Glenn

Edwards, a test pilot at Muroc Air Force Base, was command pilot

on the number one prototype YB-49. The aircraft had several

stability tests which had to be completed before this aircraft was

placed in quantity production. Scheduled stability tests were

conducted this day at 40,000 feet at a location just north of

Muroc Dry Lake. Captain Edwards radioed to base after his tests

were completed; they were dropping down to 15,000 feet. The pilot

was not heard from again. Witnesses said they saw it tumbling down

out of control just north of Highway 58 and crash. Captain Edwards

and the entire crew were killed. What exactly happened is not

known. The clean all wing design of the YB-49 enabled the aircraft

to reach very high speeds. In descending from high altitudes, the

YB-49 could easily surpass “red line” (not to exceed) air speed.

It is assumed that Captain Edwards was attempting to investigate

the stall characteristics of the aircraft, and the “not to exceed”

limits of the aircraft were exceeded while descending from 40,000

feet. In exceeding these limits, the outer wing panels were shed

and the aircraft tumbled in three pieces to the ground.

The second prototype YB-49, (S/N 42-1 02368),

was burned and destroyed during a ground taxiing

accident at Edwards Air Force Base. The YB-49 crash site can still

be seen today. Located ten miles north

of the city of Mojave and just east of Highway 14, the scorched

earth and a few bits of plastic and metal

are all that remain as a monument to this amazing design. This

crash rang the death knell for the

YB-49 Flying Wing program. Muroc Air Base was later named in honour

of Captain Glenn Edwards.

Today it is known as Edwards Air Force Base, Flight Test Centre of

the United States Air Force.

Only two YB-49’s were completed and test flown. It had a load

factor of two and a top speed of

520 miles per hour and a service ceiling of 42,000 feet. The YB-49

had eight Allison J-35-A-5

turbo jet engines. These were located in banks of four at either

side of the wing, and the only

protuberances were the exhaust along the trailing edge. Air

intakes were mounted in the leading

edge of the wing. All gun turrets, except for the tail cone guns,

were eliminated. Four vertical

stabilizing fins were fitted. The regular crew of seven were

housed entirely within the seven foot

thick wing centre section. The pilot was located in a plastic

bubble canopy near the leading edge

for excellent visibility. For long flights provision was made for

an off-duty crew of six members

who had quarters in the tail cone just aft of the flight section.

One YB-49 averaged 511 miles

per hour during a 2,258 mile flight from Muroc, California to

Washington, D. C. Flights of over

nine hours duration had been recorded.

These performances give

support to the flying wing

design. At its time it was one of the world’s longest ranging jet

aircraft.

Flying scenes of the YB-49 aircraft were featured in a Hollywood

film based upon H. G. Wells’

“War of the Worlds”. If one is privileged in viewing this on a

late show on television, you will see

an extraordinary art form of flying, banking, rolling and turning

as graceful as any plane that flew.

Watching the Flying Wing fly and perform in colour is an experience

not easily forgotten. This

author had the privilege of viewing the YB-49 flying at March

Field near Riverside, California in

May, 1947. Its grace and beauty in the air will always be a sight

to be remembered, but what

impressed most was its ability to turn inside the top Air Force

Fighter of the day -- the

P-80 “Shooting Star”.

The second prototype YB-49, S/N 42-102368, was burned and

destroyed during a ground taxiing accident at Edwards Air Force

Base. This left the YRB-49A, a strategic reconnaissance aircraft

as the sole remaining Flying Wing. This photo reconnaissance

aircraft had four 5,000 pound thrust Allison J-35-A-19 engines in

the wing and two more suspended in pods below the wing.

Photographic equipment was installed in the tail cone bay just

below the centre section. It had an empty weight of 88,500 pounds

and a gross weight of 117,500 pounds and a maximum gross weight of

206,000 pounds. It had a top speed of better than 550 miles per

hour and it was the same dimensions as the YB-49.

The clean lines of this flying wing was broken by two engine pods

suspended below the wing leading edge to carry two Allison J-35

turbo jet engines. The YRB-49-A first took to the air on May 4,

1950. Tests were conducted at Edwards Air Force Base for a period

of time, but stability tests in the program hampered further

production. Plans were made to install a stabilizing device made

by Minneapolis Honeywell to overcome stability problems. This was

the same type of device installed in the B-47 Stratojet Bomber for

stability guidance. The YRB-49A was designed as a fully

operational photo reconnaissance plane. It had useful loads and

better performance in speed and range than the YB-49. In early

1952, the huge flying wing was flown to Ontario International

Airport to the Northrop facility where the installation of this

stability device was to be installed. Funding for this project was

dropped, however, by the Air Force, and the aircraft remained in

dead storage for a period of time.

In October, 1953, the Air Force ordered the YRB-49A

to be scrapped. Crews were sent from nearby Norton Air Force Base

to complete the salvage project. The aircraft was towed from the

Northrop facility at the southeast end of the field to a site

adjacent to the Air National Guard area where it was dismantled

and cut up for scrap. The huge ship had been sitting in the grape

vineyards weathering the onslaught of dust, wind, rain and sun for

some time. One major Los Angeles newspaper stated: “It is hard to

believe we have scrapped a design which is as modern as the planes

today. Perhaps we will have to wait twenty years or longer before

we find out the true significance of our mistake.” True, the wing

did have its share of problems; however, with adequate funding,

these problems could have been worked out to prove that the wing

did hold a place with the Air Force.

The Flying Wing was years ahead of its time, but it

was caught in a budget squeeze between the faster B-47 Stratojets

and the long-range B-36 intercontinental bombers. Politics also

played an important part in the defeat of the B-49 Flying Wing.

The YRB-49A had a top speed of 512 miles per hour at 40,000 feet.

It had a range of 3,500 miles

non stop without aerial refuelling.

A comment must be made on the B-49 design competition: During this

period, 1948 - 1952, a former Northrop competitor employee became

Secretary of Defence under President Truman’s administration.

Being a former officer of a competing firm to Northrop, some

significance in the Air Force’s selection of the B-36 over the

B-49 should be noted. One day a high government official was sent

from Washington to visit John Northrop. A meeting took place

whereby John Northrop was told that his B-49 Flying Wing Bomber

would be produced for the Air Force; however, it had to be built

by Convair in Fort Worth, Texas or the Air Force would not buy his

Flying Wing design. John Northrop replied that he and his

employees had built the Northrop Company and organization over the

years and he owed a debt of loyalty to his employees. He stated

that if the aircraft was to be built at all it would be built by

his people at the Northrop factory in Hawthorne, California. The

rest is history. The Air Force ordered the B-36. The significance

of this fact should be made clear to future generations

investigating the story of the Northrop Flying Wing.

Northrop-Grumman B-2 Spirit "stealth bomber."

The

B-2 is a multi-role advanced technology bomber with stealth

characteristics. The B-2's low observable, or stealth,

characteristics give it the ability to penetrate an enemy's most

sophisticated defences. This low observability allows it to fly

more flexible routes at higher altitudes, thus increasing its

range and providing a better field of view for the crew and the

aircraft's sensors. The low observability traits of the B-2

include greatly reduced infrared, acoustic, electromagnetic,

visual and radar signatures. These signatures make it extremely

difficult for even the most sophisticated defensive systems to

detect, track and engage the bomber. Many aspects of the stealth

feature remain classified. However, the B-2's composite materials,

special coatings and flying wing design all contribute to its

stealth. The first B-2 rolled out of its hangar at Air Force Plant

42, Palmdale, Calif., in November 1988. Its first flight was July

17, 1989.

The most famous flying wing was the only successful one, the

Northrop-Grumman B-2 Spirit "stealth bomber." It was first started

by the Northrop Corporation in the late 1970s (the contract was

awarded in 1981; its first flight took place in 1989) but did not

become fully operational until a decade and a half later due to

its complexity and numerous initial problems.

The B-2 was an example of modern

technology finally catching up with an earlier idea. By the 1970s,

aircraft designers were deliberately developing airplanes like the

F-16 that were unstable in flight, and therefore inherently

manoeuvrable, controlling them in flight by sophisticated modern

computer control systems. Computer control systems now also made

it possible to control the unstable flying wing design.

The flying wing still offered

excellent performance and fuel efficiency advantages. But

Northrop's designers also chose a flying wing configuration

because it offered advantages for stealth; a vertical tail such as

found in a conventional aircraft reflects radar energy.

Eliminating it increased the aircraft's stealthiness, particularly

from the side. The B-2 is capable of carrying as many bombs inside

it as the larger B-52 and flying just as far. Although only 21 of

these planes are in service, they played a major role in the 1999

bombing of Yugoslavia, which had a sophisticated air defence

system, and are generally regarded as an amazing technological

achievement, albeit a very expensive one.

|