|

N-1M: the

first Northrop flying wing

by E.T. Wooldridge

Jack Northrop became interested in the development of the cleanest

possible airplane early in his career as an aircraft designer. In 1923, as

an engineer for Donald Douglas in Santa Monica, California, Northrop

continually explored advanced designs for aircraft, seeking new ways to

eliminate drag and the severe penalties in aircraft performance it

imposed. Even then, he envisioned an airplane without protruding surfaces

that did not contribute in some way to lift. He even undertook the design

of a tailless, all-wing glider as a "pastime" project, but never finished

the aircraft, due to other commitments and lack of funds. In 1927,

Northrop designed the incomparable Lockheed Vega as the best possible

compromise that could be made with known and proven elements. Even this

aircraft, with its conventional arrangement of wing fuselage and tail,

gave hints of the unconventional concepts that were beginning to form in

Jack Northrop's mind.

Northrop left Lockheed in 1928, and formed a small

company, the Avion Corporation, in the Burbank/Glendale area, to further

explore the idea of a tailless craft. His 1929 Flying Wing evolved, an

aircraft unusual in appearance and performance, but more noted for its

unique all-metal, stressed skin, multi-cellular construction. Although

financial considerations forced suspension of further development of the

airplane, its unique structure paved the way for major Northrop

contributions to aviation in the perfection of all-metal construction.

Noted f or its multi-cellular construction, Northrop's 1929 Flying wing,

with its twin booms and tail structure, was a cautious step toward his

first true flying wing design in 1939.

In 1932, Northrop formed a new Northrop Corporation at

El Segundo, California, in partnership with Douglas Aircraft. As Northrop

continued to design and produce airplanes of a conventional nature, he

found another opportunity to test his ideas with a wind tunnel model in

1937. He was assisted in his project, designated Model 25, by Edward H.

Heinemann, who in his own right would have a profound impact on the design

of military aircraft in the United States. Without any significant

financial support, the project was abandoned after wind tunnel tests

showed that it needed a tail.

In 1938, the Northrop Corporation became the El Segundo

division of Douglas, with emphasis on production design. More interested

in experimental design, Jack Northrop resigned, and in 1939 formed his own

company once again, Northrop Aircraft Inc. Business came in the form of

contracts for construction of Consolidated PBY subassemblies, a Norwegian

order for 24 Northrop-designed N-3PB patrol bombers in March 1940,

followed by a contract for co production of Vultee-designed Vengeance dive

bombers. Northrop finally had the financial wherewithal, facilities, and

ultimately, government interest, to enable him to pursue his interest in

research and development and more specifically in the flying wing. As

Northrop progressed through the early design stages of his first true

flying wing, he sought the advice and technical expertise of one of the

world's leading aerodynamicists, Dr. Theodore von Karman, Director of the

Daniel Guggenheim School of Aeronautics at the California Institute of

Technology (GALCIT), and von Karman's assistant, Dr. William R. Sears.

Also available were all of the technical data and information in foreign

aeronautical literature and NACA reports. Northrop and his assistant chief

of design, Walter J. Corny, conducted extensive wind tunnel tests with a

number of flying wing models. The result was an aircraft incorporating the

latest thinking on buried engine design, new airfoil sections of low drag

and improved stability, and the use of various high-lift devices,

spoilers, and flaps.

Northrop viewed the diminutive N-1M (Northrop Model 1

Mock-up), with its 38-foot wing span, as a flying scale mock-up, perhaps

one-third or one-half full-scale size. To achieve the efficiency and

economy possible with a pure all-wing design, Northrop envisioned a

commercial cargo airplane of a minimum 70-foot span, providing a maximum

thickness of about 6 feet. With wing thickness growing in proportion to

increase in span, a thickness of 15 to

20 feet would ultimately be possible. Depending on

whether the use of the aircraft would be military or commercial, gun

turrets, passenger cabins, and other special loads could be accommodated

by bumps or projections that would not alter the basic characteristics of

the aircraft.

The National Air and Space Museum is fortunate to have

in its collection one of the original models built by Jack Northrop to

investigate his theories of flying wing design. Constructed of balsa wood,

tissue paper, and cardboard, the delicate structure bears a strong

resemblance to the N-1M and incorporates many of the control surfaces

evident in the real aircraft. Hinged wing tips, cardboard flaps that serve

as rudders, and the elevons provide control and balance. The model was

tested in hand-launched free glides to test its stability and flight

characteristics.

The N-1M that evolved from many design studies and

model tests was the first such tailless configuration to appear in the

United States. The experimental aircraft was distinguished by the absence

of any of the unusual appendages; the pronounced anhedral, or downward

droop, of the wing tips gave the airplane a distinctly bird-like

appearance. Aircraft configuration could be varied on the ground between

tests to permit in-flight evaluation of the many variables associated with

wing sweep, dihedral, and the all-wing design. In effect, the N-1M was the

forerunner of today's "variable geometry" airplanes.

Control of the N-1M was accomplished using many of the

same techniques and methods employed by the Hortens in Germany and other

European designers. Elevons operated together for pitch control and

differentially for roll control. Rudder control was accomplished initially

with a plain split flap or "clamshell" at each wing tip. Actuated

independently by the rudder pedals, they opened to produce drag, which, in

turn, induced yaw. Both split flaps could also be opened simultaneously to

increase gliding angle or reduce airspeed, thus serving in the role of air

brakes.

The ICI-1M was of wooden construction, and thus easily

adaptable to the many changes in configuration to which it was subjected

during the flight test program. The aircraft was initially powered by two

submerged 65-hp Lycoming 0-145 four-cylinder, horizontally-opposed engines

driving two bladed pusher propellers by means of extension shafts. The

engines, which were later replaced by 117-hp six-cylinder, air-cooled

Franklin engines driving three-bladed propellers, were cooled by means of

slot-type intakes in the leading edge of the wing.

Engineering and construction of the N-1 M took exactly

one year, beginning in July 1939. The first flight of the N-1M, nicknamed

the "Jeep," was in July 1940, and indeed was an accidental one, as pilot

Vance Breese bounced the airplane into the air during a high-speed taxi

run on Baker Dry Lake, California.

It took only several days of abbreviated test flights

to prompt Jack Northrop to report encouraging results to Gen. H.H. "Hap"

Arnold, Chief of the Air Corps. Northrop reported the airplane was both

statically and dynamically stable about all three axes, with normal stick

forces and good controllability, laterally and longitudinally. The

aircraft was considerably shy of adequate rudder control using the

trailing edge split flap rudders, but Northrop was optimistic about a

solution.

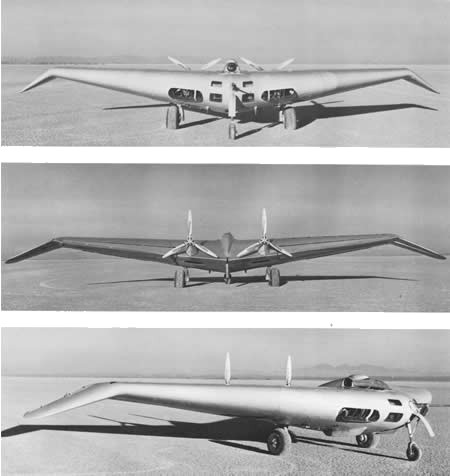

All of the N-1 M's original distinctive design features are evident in

these views of the aircraft at Muroc Lake in June 1941. Droop of 'the wing

tips, with split flap rudders installed, could be adjusted on the ground;

sweepback, dihedral, centre of gravity location (by changing angle of

sweepback), and control surface arrangement were also adjustable. The

faired tailwheel, which prevented excessive rollback on the ground, also

provided some measure of directional stability. The metal bump on the top

of the canopy was added to accommodate the pilot's head.

The N-1 M's test program provided valuable data for its

successor, the N-9M, but it was not without problems. Choosing suitable

power plants became the first, and most enduring dilemma, one that would

plague many of Jack Northrop's piston-engined tailless designs.

Jack Northrop poses by the N-1 M, while Moye Stephens beams from the

cockpit.

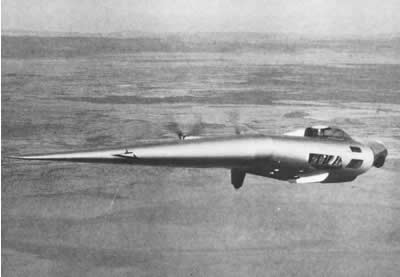

The flat surface of Muroc Dry Lake was the ideal site for early test

flights of the "Jeep," shown here cruising at an altitude of 10

feet.

At an early stage in the test program, it was

determined that the Lycoming engines were totally inadequate for the N-1

M. Moye Stephens, Northrop's company secretary and test pilot who took

over the flight test program from Vance Breese, recalls that the Lycoming

engines could not get the 4000-pound airplane any higher than ground

effect during flights at the dry lake:

"In the initial flights with the Lycoming engines the

ship would climb to about five feet and the increased induced drag

associated with attempts to force it higher would bring it down to a

landing. Continuous flight called for maintenance of a precise angle of

attack. Any increase in the angle of attack and the ship would land. Any

decrease in the angle of attack and the ship would land. The situation

was complicated by a "dead area" in elevator effectiveness. In order to

nose down it was necessary to move the wheel forward a disturbing amount

with no response, and then the elevons would suddenly take over. In order

to keep from banging into the ground it was then necessary to traverse

the dead elevator area in the opposite direction to find the start of

effectiveness. This was moderately unsettling while flying along five

feet off the ground. I temporarily overcame the difficulty by use of the

longitudinal trim flap: a control surface spanning the trailing edge of

the centre section. With this adjusted to create a nose heavy condition,

flight was maintained with a constant back pressure on the wheel. To nose

down it was simply necessary to ease off the back pressure."

Dr. Theodore von Karman quickly came up with a solution

for the problem. Realizing that the extremely thick wing was creating an

airflow separation that was not coming together until aft of the wing, he

suggested extending the trailing edge of the elevons into the closure of

the airflow. The solution apparently had the desired effect.

Early test flights were made in a straight line over

the length of the dry lake, generally at the maximum ceiling of the

aircraft, about ten feet. On one of these flights, Stephens lost one foot

of a propeller tip on the desert floor. Despite the extreme vibration

which broke a rear spar, Stephens landed the ICI-1 M without further

damage.

Replacing the Lycomings with 117-hp Franklins almost

doubled the horsepower. The engines still had to be operated considerably

in excess of the manufacturer's limitations to achieve anything

approaching satisfactory flight. Overheating became chronic, and much time

was lost in attempting to reduce oil and cylinder head operating

temperatures to acceptable limits. By May 1941, Jack Northrop had come to

the conclusion that the difficulty lay in engine design, since tests had

shown sufficient pressure drop across the engines to cool them if they had

been properly finned. Northrop considered the necessity of eventually

changing engines once again, possibly using a new Lycoming six-cylinder

engine of 150 hp. Apparently the switch never took place, since the N-1M

was received by the National Air and Space Museum in 1950 with Franklin

engines still installed.

Engine problems notwithstanding, Northrop concluded

that the flying wing as demonstrated by the N-1 M was a practical idea,

and entirely normal operation of the Flying Wing was no longer a problem.

Although Northrop leaned toward a medium-range airplane as the next

logical step, officials of the Army

Air Corps (which officially changed its name to Army Air Forces on June

29, 1941) were turning to the possibility of a long-range airplane based

on the flying wing principle. Requirements for an airplane with a range of

10,000 miles, cruising speed of 300 mph, service ceiling of 40,000 feet,

and a bomb load of 10,000 pounds were soon being discussed in the context

of a flying wing design. Northrop's feasibility studies eventually led to

a conference with Air Force Materiel Division representatives in September

1941 to consider an experimental airplane with the desired military

characteristics. The design that evolved was an incredible 140,000-pound

behemoth; a far cry indeed from the tiny 4000-pound N-1M, which only two

short years before had still been on the drawing board! Equally ambitious

was an anticipated delivery date 24 months from contract approval.

As plans materialised for

the long-range, heavy bomber, and as ICI-1M flight testing proceeded apace

under tight security conditions in the desert, an ironic sequence of

events occurred, hardly more than a footnote in the story of Jack

Northrop's flying wings. For the Horten brothers in Germane, however,

these events were a turning point in their own personal struggle to prove

the flying wing concept.

Although the Air Force

decided to classify all information pertaining to the Flying Wing in June

1941, routine publication of patent drawings had already

occurred in the Official Gazette of the U.S. Patent Office on Ma \

13. After media speculation forced an official release of information by

Northrop and the Air Force, the patent drawings and an N-1M photograph

eventually appeared in the international aeronautical journal Interavia

on November 18,1941.

When the Horten brothers

were interrogated after their capture by Allied forces in May 1945, they

referred to the appearance of the N-1 NI photograph and drawings in

Interavia as a stroke of good fortune. They used the article to

"sell" the German Aviation Ministry on a more intensive program of

development of the flying wing as a military aircraft in anticipation of

American progress along these lines. The end result was the world's first

turbojet-powered flying wing, the Horten Ho IX (Go 229), which flew in

January 1945.

The drooped wing tips were eventually straightened on the N-1 M, as these

two views of the aircraft illustrate. With maximum tip deflection and

sweepback, and the N-1 M at rest on the tricycle landing gear, the wing

tips were only one foot off the ground. Raising the nose during takeoff

lowered the wing tips until they touched the ground while the tail wheel

was still six inches in the air. Skinned wing tips during landing or

takeoff occasionally resulted.

By November 1941,

according to Jack Northrop, 200 flights had been flown with the N-1 M,

which varied in time and altitude from a few seconds and 2 or 3 feet, to

more than an hour and 7500 feet. During this time, Moye Stephens flew the

N-1M with numerous combinations of wing tip deflection, dihedral, and

sweepback. Initially it was thought that having the wing tips deflected

downward would contribute to directional stability. It was soon found that

they had little if any effect in this regard, but did lessen lift

noticeably. Consequently, they were straightened.

With an aircraft of such

radical design, stability was one of the primary concerns. In some

configurations tested, yawing the aircraft, that is, moving the rudder

pedals to cause motion about the vertical axis of the aircraft, and then

releasing the controls, induced an oscillation called "Dutch roll." The

oscillations were intense enough that Move Stephens wondered if they would

reach a point beyond which they would be impossible to stop.

Eventually, with an alternative configuration of the

aircraft, induced "Dutch roll" damped out after three or four

oscillations.'

Of equal importance was the longitudinal stability of

the flying wing. After much adjusting, experimentation, and flight

testing, a configuration was found in which longitudinal, directional, and

lateral stability were acceptable: straight wing tips, minimum dihedral,

and the greatest degree of sweepback.

Throughout the test program, investigation of the

controllability and stability of the N-1M was frequently hampered by poor

performance and engine problems. The aircraft was overweight and

underpowered, factors that required unusual approaches to some of the

everyday problems associated with flight testing.

|