|

Early

development of tailless aircraft in the United States

by E.T. Wooldridge

Until the 1930s, most of the developmental work with tailless aircraft had

been conducted in Europe. The Wasserkuppe in the Rhon mountains in Germany

particularly provided a perfect environment for the likes of Lippisch, the

Hortens, Espenlaub, Gronhoff, and others to conduct the glider experiments

they considered essential for flying wing development.

During the Depression, however, American engineers,

inventors, and tinkerers came to appreciate the potential of tailless

aircraft. With government impetus, industry and private citizens alike

joined in a new-found urge to produce safe airplanes, roadable airplanes,

and, understandably, in a record-breaking era, airplanes that would go

farther and faster with greater payloads. It was perhaps inevitable that

many far-sighted designers would see in the designs for tailless aircraft

or flying wings the solutions to their problems.

One of the first American designers to capitalize on

the "flying wing" mystique was Vincent J. Burnelli. In the 1920s, Burnelli

produced two biplane transports with large, airfoil-shaped fuselages that

contributed a considerable portion of the airplane's lift. His goal was to

develop a more efficient airplane that could carry a large payload.

Although Burnelli referred to his lifting body transports as "flying

wings," his production aircraft invariably retained some kind of a tail,

frequently supported by upswept booms that extended rearward.

Burnelli's first monoplane, the CB-16, appeared in

1928. This aircraft and subsequent Burnelli types produced into the 1940s

had certain features in common. The engines were close together and ahead

of the cabin structure. The airfoil fuselage section, which provided 50

percent lift at cruising speed, housed the passenger cabin and the pilot's

and mechanic's compartments. More than 60 percent of the weight and

strength of the aircraft structure surrounded and protected the passenger

cabin section for maximum resistance to telescoping. Burnelli maintained

that his lifting design had unparalleled safety, economic, and operational

advantages over conventional transport designs. His design philosophy was

supported by many prominent civil and military aviation experts well into

the late 1940s, but he failed to gain the political and economic backing

that would have ensured public acceptance of his unconventional designs.

Powered by two 3 cylinder, 35 hp Anzani engines, the de Monge 7.4 carried

two side-by-side seats and luggage space in the wing centre section.

The French de Monge (later Dvle and Bacalan) aircraft of the 1920s were

more technically advanced than their American Burnelli counterparts.

Despite Burnelli's claims to a virtual monopoly on the

lifting body design, it is interesting to observe similar efforts carried

on in France concurrently with Burnelli's work in the 1920s and early

1930s. Louis de Monge built a clean, lifting body monoplane with a

cantilever wing in 1924, at the same time Burnelli was producing the RB-2

biplane. The de Monge 7.4 was built as a flying scale model of a proposed

transatlantic airliner. In 1925, the Dyle and Bacalan shipyard at Bordeaux

acquired the rights to the de Monge design and subsequently produced a

variety of civil and military lifting body aircraft covering the range

from twin to four-engine configurations. As the models were scaled up,

however, clutter appeared in the form of struts, gun mounts, and cockpits,

and performance suffered proportionally.

Vincent J. Burnelli was known for his unattractive, but functional

"lifting fuselage" transports of the 1920s and 1930s. His RB-2 of 1924 was

capable of carrying 6000 pounds of freight, a remarkable feat in its day.

Shortly after Burnelli produced his first "flying

fuselage" monoplane, an unusual machine with a superficial resemblance to

the Burnelli appeared in the sky over the Mojave Desert, California. Jack

Northrop's 1929 Flying Wing had a wing centre-section thick enough to

enclose the crew and the engine. Since it had a tail carried on two

slender tailbooms, the aircraft was not a true flying wing, although it

was widely touted as such in aviation magazines of the day. Nonetheless,

the airplane was obviously unconventional, having been built primarily as

a flying laboratory to test structural innovations and unusual

arrangements of various components of the airplane.

Burnelli's 1935 UB-14 represented the ultimate in construction of his

airfoil fuselage design. The airfoil fuselage provided 50 percent of

the total lift at cruising speed, while providing seating capacity

for two pilots and 14 passengers. Two Pratt & Whitney Hornet radial

engines provided 680 hp and a maximum speed of 235 mph.

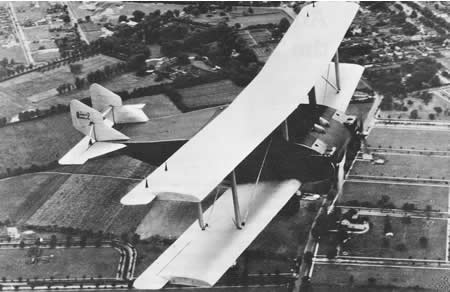

The Northrop 1929 Flying Wing was designed by Jack

Northrop and W.K. Jay during the latter part of 1928. Its early

development and tests were carried on by the Avion Corporation, financed

in part by newspaper publisher George Hearst, who was president of Avion,

with Jack Northrop as vice-president. Northrop experimented with both a

pusher arrangement of the Mark III Cirrus engine, specially inverted by

Menasco Motors, Inc. of Los Angeles, and a Menasco A-4 four-in-line

inverted engine driving a tractor propeller. In either configuration,

cooling air passed through a large tunnel extending entirely through the

wing from the front opening in the engine cowling to an opening just ahead

of the trailing edge on the lower side of the wing. This cooling

arrangement proved satisfactory, and a material reduction in drag was

effected by enclosing the engine.

Jack Northrop's 1929 Flying Wing was touted as such, but it still relied

upon conventional ailerons and rudders for control. The all-metal airplane

employed a newly developed type of structure in which the reinforced

duralumin skin provided both covering and most of the structural strength

of wings and tail structures. In this photograph the right hand cockpit

has been covered up for the test flight.

Initial flight tests were conducted at Muroc Dry Lake

on the Mojave Desert with test pilot Eddie Bellande at the controls. Later

flights were made from the United Air Terminal, Burbank, California. The

aircraft demonstrated normal flight characteristics in every respect, and

general performance was above average. Maximum speed was approximately 25

percent better than any other design of like power and capacity. Much of

the engineering data obtained during flight tests of the airplane

contributed directly to the design of Northrop's first real flying wing 10

years later.

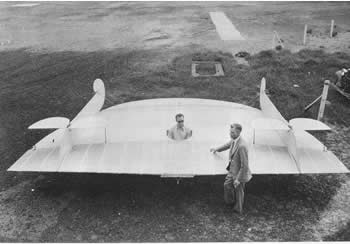

Jack Northrop discusses flight test results with test pilot Eddie Bellande.

In the pusher configuration, the propeller was connected to the engine by

means of a seven-foot shaft extending between the two cockpits. Original

retractable landing gear, designed by Northrop and built by Menasco

Motors, was later replaced by a fixed gear in the Flying Wing

On September 22, 1930, Northrop advised the Civil

Aeronautics Authority that flights with the airplane would be discontinued

pending wind tunnel and laboratory tests. No further records are available

for the first of Jack Northrop's flying wings. Few of the southern

California aviation pioneers of the 1920s shared Jack Northrop's budding

enthusiasm for the flying wing. There was one man, however, who not only

believed in the concept, but may have been responsible for selling Jack

Northrop on the idea.

Anthony (Tony) Stadlman was a Czechoslovakian who had

immigrated to the United States in 1905 at the age of 20. In 1910, he

began a career in aviation that ultimately involved him in practically

every phase of the business: maintenance, construction, design, and an

abbreviated but eventful stint as pilot. In 1918, Stadlman joined Loughead

(pronounced Lockheed) Aircraft Manufacturing Association with the Loughead

brothers, Allan and Malcolm, and a young draftsman just out of Santa

Barbara High School, John K. Northrop. This association led to the

development of the monocoque fuselage used so successfully in the Lockheed

Vega that was to follow years later.

Anthony Stadlman poses in 1929 with a model of his design for a

tailless aircraft obvious similarities between the Stadlman and Northrop

1929 flying wings.

In 1923, three years after the dissolution of the

Loughead firm, Stadlman and Northrop worked together for Donald Douglas in

Santa Monica, California. For years Stadlman had been intrigued by the

early efforts of JAV. Dunne to develop a successful tailless aircraft.

Stadlman continued his research and study of tailless aircraft during his

tenure at Douglas. Stadlman and Northrop became good friends, with

Northrop eventually sharing Stadlman's enthusiasm for tailless aircraft.

Working together, the two engineers built a set of wings for a tailless

aircraft, a project that was never completed.

In 1926, with the Anglicised spelling of Loughead now

legalized, Lockheed Aircraft Corporation was back in business once again,

with Allan Lockheed, Stadlman, and Northrop working together to build the

famous Vega. Preoccupation with the Vega left little time to

explore the potential of the flying wing. But in 1928, Northrop left

Lockheed to form the Avion Corporation, and his 1929 Flying Wing soon

followed. Stadlman left in 1929 to devote more time to his own flying wing

designs.

Finally, in August 1929, "Tailless Tony" Stadlman

enjoyed a brief but well-deserved flurry of publicity for his concept of

the flying wing cargo and passenger aircraft of the future. Newspapers in

San Francisco, Los Angeles, and Chicago, in August and September 1929,

proclaimed Stadlman's progress in the design and construction of a flying

wing that would revolutionize air transportation. Tony posed for

photographs holding a model of his tailless design, a design that he and

Jack Northrop had discussed and worked over during countless hours

together during their Douglas and Lockheed years.

Unlike Northrop's 1929 Flying Wing, Tony Stadlman's

design never got airborne. He did go on to have a very successful career

in aircraft construction, but, until his death in September 1982 at age

96, he remained disappointed over the circumstances that kept him from

realizing his dream of the true flying wing. He could take some measure of

satisfaction, however, from the knowledge that his ideas on tailless

aircraft were appreciated by the one man whose name became synonymous with

the flying wing.

A derivative of early Burgess and Dunne designs, the 1930 Arrowhead Safety

Airplane was also inherently stable, weighed only 850 pounds and landed at

a low 22 mph.

A throwback to the era of Burgess and Dunne was the

1930 Arrowhead Safety Airplane. The similarity to the Burgess-Dunne

designs of 1914-1916 was not coincidental, since an assistant designer on

the project was one J.W. Davis, formerly of the Burgess Aircraft Company

of Marblehead, Massachusetts. The builder was a former U.S. Marine Major

B.L. Smith, who described his design as a flying wing that he hoped would

be "economical and safe, in which pilots can be taught to fly in a short

length of time at low cost." The design claimed the interest of Glenn H.

Curtiss, with whom Davis was connected in real estate development.

Curtiss, whose interest in a roadable airplane went back to 1911, died

before the first flight of the airplane, and although the Arrowhead made

34 flights by the end of 1930, interest waned and another "foolproof"

airplane faded away.

Safe flying for everybody emerged from the chrysalis of

past dreams and became a living, vibrant actuality today when a new type

of airplane before a throng of notables at Glenn Curtiss Airport, North

Beach, Long Island, convinced the most sceptical experts that it could not

dive or stall or spin-the causes of nearly all accidents.'

This rather dramatic press release from the Merrill

Aircraft Company of New York City on February 11, 1931, announced the

public demonstration of yet another "flying machine that could be landed

safely under all circumstances, even with utterly inexpert piloting." The

key to the aircraft's stability and control lay in its wings.

Designer Albert Merrill explained: "If we move the

stabilizer forward, progressively increasing its size until it becomes a

lower wing located somewhat behind the upper wing, i.e., with `stagger'

and angularity to the upper wing, i.e., `decalage' we have a ship that is

equally stable in any position."

The two wings of the aircraft were not integrated with

the fuselage, and the entire biplane wing structure could be tilted up or

down by the pilot to a maximum angle of 14 degrees. Pitch control of the

airplane was thus obtained by altering the angle of the wings relative to

the fuselage rather than by altering the angle of the entire fuselage

relative to the ground as is generally done with the elevator. Both wings

moved as a unit; no alteration of the relation of upper and lower wings

was possible. By limiting the lower and upper limits of wing travel with

mechanical stops, safe flight was more or less assured within the range of

practical flying.

According to Merrill: "So long as you fly within these

limits nothing can stall or nose the machine and this means safety!" If

the occasion arose when it was necessary to exceed the limits of wing

movement, as in an emergency or to perform aerobatics, an elevator was

available for control. There was, however, no fixed horizontal tail

surface.'

Twelve years of research and testing by Albert Merrill

led to this experimental movable-wing biplane, renowned for its safety

features. In the upper photograph, the wings have been rotated so that

they are at the highest angle of incidence, with the bottom-wing forward,

and the top wing aft. In the lower photograph, the wings have been rotated

to the other extreme, i.e., the lowest angle of incidence. The bottom wing

is aft, the top wing is now forward. Safe flight was assured between these

two extremes.

Albert Merrill had been experimenting in aeronautics

since 1894, when he first became associated with Octave Chanute, Samuel P.

Langley, and Otto Lilienthal, all members of the Boston Aeronautical

Society. After a near-fatal flying accident in 1911, Merrill became

convinced that the conventional control system was wrong, and he devoted

many years to designing, building, and testing experimental aircraft to

prove his theories. The first of these was a tailless, tractor biplane

with a pronounced stagger. Though not a complete success it did show

distinct possibilities; inherent stability was obtained within a limited

flying range.

Merrill's efforts to design a longitudinally stable,

yet fully controllable, airplane continued during his tenure as a faculty

member at California Institute of Technology. Tailless gliders were built

to test his theories of control. One such glider prompted an exchange of

correspondence in 1924 between Professor Merrill and rocket pioneer Robert

H. Goddard, who at the time was performing the research that led to the

world's first liquid propellant rocket in 1926. Merrill prevailed upon

Goddard to furnish drawings for a 60-pound thrust rocket for one of his

tailless gliders, the purpose of which would be to extend the glider's

soaring endurance while waiting for the "next gust." In response, Goddard

recommended a light reciprocating engine as a power source. Undaunted,

Merrill repeated his original request, but Goddard never did the drawing.

A more conventional combination of power plant and

airframe evolved in 1926 with Merrill's first movable-wing biplane.

Further research on various wing combinations led to refined biplane

models in 1928 and 1931, and a monoplane followed soon thereafter.

Despite the "gasps of wonder" which public

demonstrations of Merrill's fool-proof airplane generally evoked from the

audience, financial support never really materialized for the project.

After an absence from Cal Tech, Merrill returned there and remained until

his retirement. He died in 1952, respected by his peers as a pioneer

aviation enthusiast and professional aerodynamicist.

Not all designers were seeking the safe, fool-proof

airplane. Charles F. Rocheville and Clare K. Vance sought exceptional

range, endurance, and payload, and in so doing, followed in the footsteps

of Burnelli. Rocheville was a designer, inventor, entrepreneur, and pilot.

Among the many innovative aircraft designs he produced was his 1930 Emsco

B-8 Flying Wing, designed while he was vice president of Emsco Aircraft

Corporation. A twin-boom configuration was used to connect a single-fin

empennage to a 60-foot wing, upon which perched a streamlined nacelle with

tandem cockpits. Equipped with reverse tricycle landing gear, the aircraft

employed an unusual "blown wing" system, in which air was inducted aft of

the engine cowling, carried through the wing, and ejected out of slots set

one-third of the way forward of the trailing edge.

Clare Vance's flying wing carried 1200 gallons of fuel in its thick centre

section, sufficient for a non-stop range of 7500 miles. Vance designed and

built the craft from models whittled out of wood while he flew the mail

across the mountains.

Rocheville intended to improve the existing

non-refuelled endurance record of 65 hours 20 minutes; he would follow

this feat with an attempted non-stop flight from Japan to America, a

distance of almost 5000 miles. Despite favourable flight tests, the

project was terminated in 1930 for financial reasons before any record

attempts could be accomplished.

Two years later, renowned air mail pilot Clare K. Vance

unveiled his own version of a flying wing that bore a superficial

resemblance to the Emsco aircraft. The Vance airplane was not as

technologically advanced as the Emsco, but seemed well suited as a

long-haul freight carrier. Vance claimed a top speed of 200 mph and fuel

capacity for a 7500 mile range. After a successful series of test flights,

Vance competed unsuccessfully in the 1932 Bendix Trophy race before his

death in December 1932. The airplane was subsequently modified and was

entered in, but did not complete, the 1933 and 1934 Bendix races.

A podiatrist from South Bend, Indiana, was responsible

for one of the more distinctive and successful tailless designs of the

Depression. Dr. C.L. Snyder, intrigued with the flying qualities of a felt

heel lift that he had idly tossed through the air one day in 1926, pursued

his idea from the primitive model stage to unpowered and powered gliders,

and finally to several highly successful disc-type aircraft.

Dr. Snyder's first aircraft was known as the Dirigiplane, Monowing, and

finally Arup S-1, at various stages of its development. Rudders are at the

after edges of-the vertical stabilizers; elevator extends

across the wing trailing edge; ailerons are at the top of the vertical

stabilizer, forward.

Like Junkers, Soldenhoff, and Rumpler, Snyder's goal

was to develop of the flying wing for air transport purposes. He

envisioned an aircraft with a wing 15 feet thick with a 100-foot span and

a 100-foot chord. The passengers were to be seated in the wing with a

clear view forward through the plastic leading edge of the wing. Snyder's

early glider experiments led to the formation of the Arup Manufacturing

Corporation in 1932 to refine his initial experimental configuration to a

practical aircraft. Aided by the engineering skills of Raoul Hoffman and

with Glenn Doolittle (racing pilot Jimmie Doolittle's cousin) acting as

test pilot, Dr. Snyder produced three more variations of the basic

disc-shaped Arup S-1 powered glider. Of the three, Arup S-2 and S-4 proved

to be more durable and practical, making hundreds of flights during the

mid-1930s, including impressive demonstration flights for the NACA, CAA,

and the Army.

The Arup experienced an accident-free service life.

Some of its pronounced advantages over more conventional aircraft were

greater lift and safety, increased cruising range, lower takeoff and

landing speeds, and stall-proof flight characteristics. Dr. Snyder's Arups

were not commercial successes, however. He had inadequate working capital,

inexperienced management, and an aircraft that just did not "look right."

Arup S-4 (foreground) demonstrates the practicality of a low aspect ratio

wing. Both Arup S-2 (background) and the S-4 were frequently used as

flying billboards during their accident-free careers.

Raoul Hoffman, Dr. C.L. Snyder's engineer at Arup, left

that company in 1933 and moved to Florida where he designed an Arup-type

aircraft for a Chicago industrialist. The Hoffman flying wing, like the

Arups, had performance figures that were guaranteed to appeal to those

citizens who wanted to replace the family automobile with an "air

flivver." Unfortunately, Hoffman's aircraft caught fire in flight from a

broken fuel line and crashed, killing the pilot.

Dick Atkins of the Vought Aircraft heritage Foundation

writes:

In 1939-1940 era, this machine was stored in the old

Goodyear blimp hangar at the Albert Whitted airport in St. Petersburg,

Florida.

My 2 buddies (Julius Smith and Ronnie Sampson) and I ( aged 14) were

aviation nuts a spent every waking hour at the AW airport. We would sneak

into the blimp hangar (The Goodyear blimp had relocated to another base)

and play in the old National Airlines Stinson Trimotors and the Arup-type

which everyone called "The Bat."

One day we were climbing on the "Bat" when Rex McDonald, of McDonald

Flying Service (who had a lean-to office just inside the entrance to the

blimp

hagar) saw us and ordered us off the machine and made the remark; "don't

want you to fall through the fabric....on the other hand, that might save

someones life." That was a very prophetic observation.

Sometime later (never knew what prompted this) the "bat" was outside the

hangar being prepared for flight. The pilots was Sam Huey, a 19 year old

instructor who worked for Jimmy Johnstone Flying Service. He took off,

thottled back to climb power and the nose dropped. He went back to full

power and came back for a landing. Just after turning final the airplane

erupted in flame, rolled inverted and out came Huey. he was too low for

his chute to deploy and fell to his death. The airplane crashed into the

Bayboro Boat works.

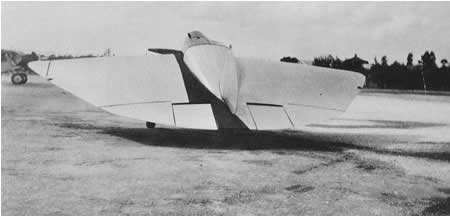

Built in St. Petersburg, Florida, this unusual tailless aircraft resembled

the Arup disc designs. A 1934 design by former Arup engineer Raoul

Hoffman, the wing was a semicircle to which floating tip controllers were

added to serve as ailerons. Elevators were located in the wing's trailing

edge.

Walter F. McGinty of Batwing Aircraft Company also had

an eye on the "air flivver" market. His X-1, a two-place tailless

aircraft, featured a hydraulic extension of the nose gear to facilitate

landing and taking off in a restricted space. Powered by a 40-hp Pobjoy

engine, the aircraft was reported to have gotten just one foot off the

ground at the end of a 6000-foot runway!

Batwing Aircraft Company, headed by Walter F. McGinty, constructed this

tailless model in the late 1930s. Vertical surfaces at the wing tips

served as rudders and airbrakes. Wing-mounted elevons acted as elevators

and ailerons. The craft was similar in appearance to Waldo Waterman's

Arrowbile, but was not roadable. A twin-engine design was projected but

not built.

Neither Arup, Hoffman, nor McGinty developed the first

truly functional flying automobile. The credit for this remarkable

achievement is generally given to Waldo D. Waterman of California, who for

many years had visualized the development of a simple, safe, and cheap

airplane for the average private pilot. Waterman felt the solution lay in

a design based on the tailless concept.10 In 1932, he built an

aircraft that was not only the first successful tailless monoplane in the

United States, but was the first step toward a practical design for a

tailless aircraft that could also be adapted to a flying automobile.

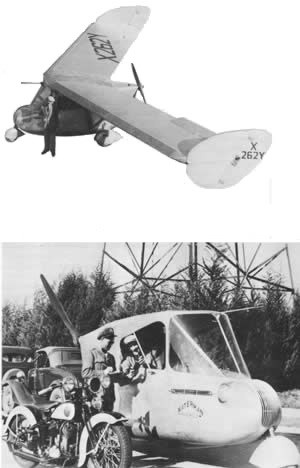

Waldo Waterman's Arrowbile was completed in February 1937, and was

successfully flight tested. Waterman had to design a gear reduction system

to transmit power to the rear wheels, a de-clutchable propeller, and

detachable wings. He was also required to conduct extensive road tests

(below). The Arrowbile also featured a Studebaker automobile engine,

radiator, dashboard instruments, and body trim.

Waterman's 1932 prototype, nicknamed "Whatsit" for its

unconventional nature, led to the 1935 "Arrowplane" designed and built for

the U.S. Department of Commerce Safety Airplane competition. Powered by a

Menasco C-4 95-hp engine, it was flown from Santa Monica to Washington,

D.C., in July 1935, winning an award for Waterman. Once the airworthiness

of the design had been proven, Waterman turned to the task of adapting the

design for surface use. The first "Arrowbile" was completed and flown by

Waterman on February 21, 1937. It proved to be stable, difficult to spin

or stall, and possessed all the manoeuvrability required for normal

flying. Equally important, the airplane conformed to laws for operation on

the highways. Waterman's financial problems and poor health, and World War

II, interrupted the orderly development of the "Arrowbile," but a final

variant, the "Aerobile" appeared in 1957. The "Aerobile" was a three-place

machine with a liquid cooled Franklin engine and a single-piece wing. A

one-of-a-kind aircraft, the "Aerobile" was flown successfully many times

before it joined the "Whatsit" at the National Air and Space Museum in

1961.

John D. Akerman's tailless aircraft of 1936 deserves a

passing mention if only to illustrate the wide diversity of factors that

led to construction of such aircraft. Akerman, a professor in the

Department of Aeronautical Engineering at the University of Minnesota, did

not design a tailless aircraft for inherent stability or safety of flight,

nor did he want a flying automobile or transoceanic airliner. He designed

his tailless airplane to provide employment under the Public Works

Administration work program for several airplane mechanics and some

aeronautical engineering students!

Akerman's selection of a tailless design was motivated

by his opinion that a real tailless aircraft had never been built in the

United States or England. He discounted the work of Dunne, Hill, and

Waterman, because the wings were so swept back that the wing tips were, in

effect, two tails. Akerman acknowledged the work of Germany's Alexander

Lippisch with the delta concept, and incorporated the delta shape in his

airplane.

The Akerman design consisted of wing tip rudders,

elevons, and centre section flaps that were used in conjunction with the

elevons for pitch control. The centre section flaps, which were controlled

by a lever in the cockpit, could also be used to trim the airplane for

balanced flight. The wing, which was a modified delta, had a fixed leading

edge slot.

Professor John D. Akerman conducts taxi tests in his experimental tailless

aircraft in 1936. During its single test flight, the radical design

demonstrated normal takeoff characteristics, satisfactory horizontal

flight, good lateral control, and good stall characteristics during

landing.

One brief, harrowing flight was made by Professor

Akerman at Wold Chamberlain airport in Minneapolis, Minnesota in 1936.

Once airborne, the aircraft appeared to fly normally in straight and level

flight at an altitude of 15 feet. Unfortunately, a news cameraman

following along the runway created the possibility of a collision, so

Akerman prudently cut the engine and landed. University officials were

highly upset, fearing that the professor had exposed the University to

possible liability by flying the experimental aircraft without proper

qualifications. It was the beginning and the end of the Akerman tailless

airplane. There were no more flights; the airplane was placed in storage,

and another brief episode in the history of tailless aircraft came to a

close. As a tribute to the pioneering efforts of Professor Akerman, the

airplane was refurbished and donated to the Smithsonian Institution in

1970.

In 1937 the Management and Research, Inc. Model H-70-71

(NX-20399) tailless monoplane was manufactured for the U.S. Department of

Commerce. It was one of many prototypes that appeared briefly in the

thirties. The airplane was a derivative of the 1936 Stearman-Hammond Y, a

product of the Bureau of Air Commerce light plane development program. The

wing was nearly rectangular, with two pairs of flap-type controllers

fitted in the straight trailing edge. A pair of rudders were mounted over

each wing. Powered by a Menasco 95-hp engine, the aircraft allegedly had a

top speed of 100 mph.

Test pilot James B. (Jimmie) Taylor inspects the tailless Management and

Research Model H-70-71 monoplane at Floyd Bennett Field, New York, 01st

April 15, 1938. The aircraft had crashed on January 27, 1938, and had been

subsequently rebuilt by Tuscar Metals, Inc. prior to resumption of the

flight test program at Floyd Bennett Field.

The airplane had an undistinguished flying career.

Although official Civil Aeronautic Administration certificates indicate

NX-20399 was owned by Management and Research, Inc. until its destruction

in August 1945, the aircraft was referred to in the press, and in some

Department of Commerce papers, as the Tuscar Metals, Inc. Model H-71.

Regardless of proper ownership, the airplane proved difficult to fly, and

required the skilled hands of one of America's most distinguished test

pilots, Jimmie Taylor, at the controls during much of the flight test

program. By November 1944, it had accumulated about 50 to 60 hours of

flying time, and less than a year later, was totally destroyed in a crash

in August 1945, thus ending its service life without making any

significant impact on flying wing design.

Notwithstanding the efforts of Waterman, Snyder,

Hoffman, and others, tailless aircraft were not accepted in the

marketplace. Neither government nor industry displayed the sustained

interest or provided the timely support that would have ensured some

success.

|