Aircraft Engines

Pistons in cylinders first saw use in

steam engines. Scotland's James Watt crafted the first good ones during

the 1770s. A century later, the German inventors Nicolaus Otto and

Gottlieb Daimler introduced gasoline as the fuel, burned directly within

the cylinders. Such motors powered the earliest automobiles. They were

lighter and more mobile than steam engines, more reliable, and easier to

start.

Some single-piston gasoline engines

entered service, but for use with airplanes, most such engines had a

number of pistons, each shuttling back and forth within its own cylinder.

Each piston also had a connecting rod, which pushed on a crank that was

part of a crankshaft. This crankshaft drove the propeller.

The cylinder is closed on one end (the

cylinder head), and the piston fits snugly in the cylinder. The piston

wall is grooved to accommodate rings which fit tightly against the

cylinder wall and help seal the cylinder's open end so that gases cannot

escape from the combustion chamber. The combustion chamber is the area

between the top of the piston and the head of the cylinder when the piston

is at its uppermost point of travel.

The up-and-down movement

of the piston is converted to rotary motion to turn the propeller by the

connecting rod and the crankshaft, just as in most automobiles. Note the

crankshaft, connecting rod, and piston arrangement and

imagine how the movement of the piston is converted to the rotary motion

of the crankshaft. Note particularly how the connecting rod is joined to

the crankshaft in an offset manner.

The valves at

the top of the cylinder open and close to let in a mixture of fuel and air

and to let out, or exhaust, burned gases from the combustion chamber. The

opening and closing of a valve are done by a cam geared to the crankshaft.

This gearing arrangement ensures that the two valves open and close at the

proper times.

Engines built for airplanes had to

produce plenty of power while remaining light in weight. The first

American planebuilders—Wilbur and Orville Wright, Glenn Curtiss—used

motors that resembled those of automobiles. They were heavy and complex

because they used water-filled plumbing to stay cool.

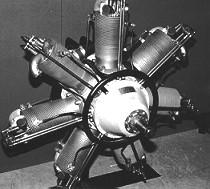

Gnome rotary

A French engine of 1908, the "Gnome,"

introduced air cooling as a way to eliminate the plumbing and lighten the

weight. It was known as a rotary engine. The Wright and Curtiss motors had

been mounted firmly in supports, with the shaft and propeller spinning.

Rotary engines reversed that, with the shaft being held tightly—and the

engine spinning! The propeller was mounted to the rotating engine, which

stayed cool by having its cylinders whirl within the open air.

During World War I, rotaries attained

tremendous popularity. They were less complex and easier to make than the

water-cooled type. They powered such outstanding fighter planes as

German's Fokker DR-1 and Britain's Sopwith Camel. They used castor oil for

lubrication because it did not dissolve in gasoline. However, they tended

to spray this oil all over, making a smelly mess. Worse, they were limited

in power. The best of them reached 260 to 280 horsepower (190 to 210

kilowatts).

Thus, in 1917 a group of American engine

builders returned to water cooling as they sought a 400-horsepower

(300-kilowatt) engine. The engine that resulted, the Liberty was the most

powerful aircraft engine of its day, with the U.S. auto industry building

more than 20,000 of them. Water-cooled engines built in Europe also

outperformed the air-cooled rotaries, and lasted longer. With the war

continuing until late in 1918, the rotaries lost favour.

Liberty engine

In this fashion, designers returned to

water-cooled motors that again were fixed in position. They stayed cool by

having water or antifreeze flow in channels through the engine to carry

away the heat. A radiator cooled the heated water. In addition to offering

plenty of power, such motors could be completely enclosed within a

streamlined housing, to reduce drag and thus produce higher speeds in

flight. Rolls Royce, Great Britain's leading engine-builder, built only

water-cooled motors.