|

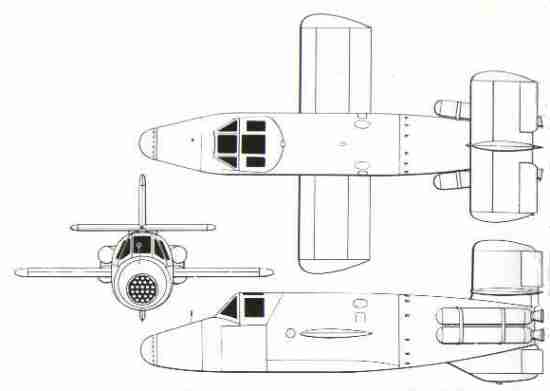

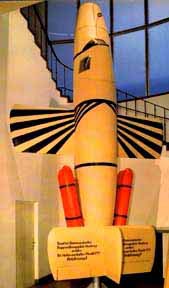

Bachem Viper Natter

In reality, only one

experimental vertical takeoff interceptor was available in 1944. This

simple innovative project designated Bachem Projekt 20, which was

accepted by the Air Ministry and received the official RLM designation

Ba 349, was code-named Natter (Viper). It was manufactured in small

numbers prior to the end of the war. A second design with vertical

takeoff capability, the He P 1077 (see p. 152), failed to materialize

except for a few gliders that may have been completed prior to the

war's conclusion.

The Bachem Werke GmbH was founded on February 10, 1942, by Dipl.-Ing.

Erich Bachem, formerly the Technischer Direktor of the Fieseler firm.

The company manufactured spare parts for piston-engine fighters and

other aircraft equipment before the Natter project was created.

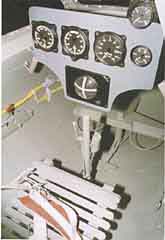

The BP 20 was projected

as a small lightweight expendable interceptor, capable of destroying

any enemy bomber using the least possible weapon expenditure. To achive

this objective, this ambitious project employed a vertical

rocket-assisted takeoff followed by separate descent and landing of

pilot and aircraft by separate parachutes. It was believed that pilots

having little or no experience would need only rudimentary flight and

gunnery instruction, rather than spending valuable training resources

on the finer points of flight training. Erich Bachem reasoned that, a

reasonable number of such interceptors and launch sites could be

installed around key industrial targets, to make attacking Allied

bombers pay a prohibitively high price. Other attributes of Natter

included savings in the amount of steel and aviation fuel and the

ability to be quickly transported from small, camouflaged sites. The

ability to recover the rocket motor for reuse was considered an

important feature of this aircraft, which was essentially a manned

missile.. There were even plans to launch the interceptor from ships if

the need arose.

The BP 20 was of wood

construction and was to be built without the use of gluing presses.

Most of the parts could be made in small woodworking shops through

Germany, without interfering with the existing needs of the aircraft

industry. According to Erich Bachem, ) only 600 man-hours were required

for the production of one airframe, excluding the HWK 509 A-2 rocket

motor, which was a relatively simple to manufacture when compared to

sophisticated turbojet.

The fuel capacity was

to consist of 119 US gallons (450 litres) T-Stoff and 66 US gallons

(250 litres) C-Stoff, carried in separate tanks. The available fuel was

sufficient for 80 seconds at full power, developing a thrust of about

3,750 lb (1,700 kg). Takeoff assistance was provided by four solid-fuel

rockets SR 34 which produced an additional thrust of 2,200 lb (1,000

kg) for twelve seconds.

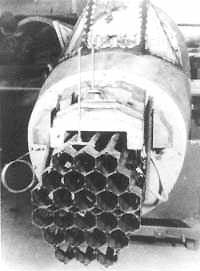

Natter's weapon systems

were simple and potentially devastating. They comprised either a

honeycomb 24 electrically fired 73 mm F6hn air-to-air rockets, or 32

R40 air-to-air missiles located behind a jettisonable cover in nose

section. The alternative, the Rheinmetall SG 119 consisted of six

clusters, each cluster containing seven MK108 barrels grouped together

in a cylinder with the clusters arranged about the Viper's nose as in a

revolver.

Bachem submitted his

Natter project to the OKL and simultaneously to the SS-F6hrungshaptamt

(SS Planning Office), in August 1944. One month later, a contract for

fifteen experimental BP 20 aircraft was awarded, and a few weeks later,

Natter was included in the J5gerNotprogramm (Emergency Fighter

Program). The first experimental aircraft, the Ba 349 M1 and M2, were

under construction in October 1944, at a time when the RLM believed the

Natter could be successfully employed against Allied heavy bombers,

including the anticipated American Boeing B-29.30 The first batch of

fifty Ba 349s was ordered for delivery between October 1944, and

January 1945. A measure of the importance attached to the program is in

the substantial order of 200 Vipers at the start of mass production.

The installation of

parachutes delayed flight testing of the first target defence

prototype, the Ba 349 M1, until November 1944. The Ba 349 M2 was

completed soon thereafter and the first takeoff under air-tow of the

third prototype, Ba 349 M3, was made at Neuburg on the Danube on

December 14, 1944. A second flight behind a He 111 by the DFS, followed

eight days later. After successful completion of ground tests near Bad

Waldsee on December 18, 1944, the first vertical launch from a ramp was

scheduled. This event was marred when the Viper caught fire as a result

of a technical fault. The next attempt was made four days later at

Heuberg Hill near Stetten am kalten Markt. The aircraft was towed to an

altitude of 2,460 ft (750 m) and parachutes were deployed to carry the

Viper and its simulated pilot safely to ground. The second takeoff

occurred on December 29, 1944, without serious incident while

simultaneously, other Vipers were towed into the air for further

testing.

French armor advanced

into Waldsee on April 1945 and a great number of spare parts was

captured- Only a few days before the French arrived, fifteen rocket

engines destined for Vipers had been thrown into Lake Waldsee to

prevent their capture. The secret was not well kept however and all

were later recovered.

Plans for mass production of the Ba 349 A-1 were authorized on March 1,

1945, but only a few Natters were actually completed. These were

followed by the improved Ba 349 B-1 (Entwurf 2) interceptors whkb were

to be produced at Waldsee, but few were actually completed.

On of the models were powered by a solid-fuel rocket to evaluate

takeoff characteristics. Practical tests carried out at Peenemunde,

where a first test conducted during February 1945, proved unsuccessful.

Willy A. Fiedler, a testing engineer working for the RLM, was sent to

the Heuberg Hills to oversee the program Erich Bachem is quoted after

the war as having said that about twenty Vipers had been used for

practical tests. Fifteen were of the A-series, and four B-series

aircraft. All were constructed at Waldsee. Still others were assembled

by the Wolf Hirth glider factory. Four additional Ba 349s, possibly of

the B-series, were captured at the end of the war by Allied forces near

St. Leonhard, Austria

.

Origin: Bachem-Werke GmbH,

Waldsee

Type: part-expendable target-defence interceptor

Engine: 2,000kg thrust Walter HWK 109-509C-1 bi-propellant rocket

(vertical launch boosted by four 500kg or two 1,000kg solid motors

Armament: 24 Föhn 73mm spin-stabilized rockets, or 33 R4M 55mm

spin-stabilized rockets, or (projected) two 30mm MK 108 cannon each

with 30 rounds

Speed: maximum speed (sea level) 800km/h, (at high altitude) 1,000km/h

Climb: 11,100m/minute

Range: 32-48km

Weight: empty 880kg, loaded 2,232kg

Wingspan: 3.6m

Length: 6.02m

Height: 2.25m

Crew: one |