|

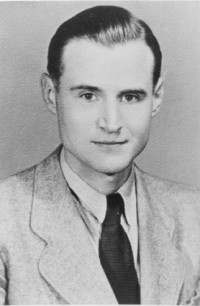

Hans

von Ohain

thanks to

Wikipedia

Hans Joachim Pabst von Ohain

(December 14, 1911 March 13, 1998) was one of the

inventors of jet propulsion. His HeS 1 design was the first

self-contained jet engine to run, and the later HeS 3 was

the first to power an all-jet aircraft. Although none of his

designs entered production, his contributions to the

development of the jet engine in Germany are invaluable.

After the war he met his British counterpart, Frank Whittle,

and the two became good friends.

Born in Dessau, Germany, he earned a Ph.D. in Physics and

Aerodynamics from the University of Göttingen, then one of

the major centers for aeronautical research. During his

studies, in 1933 he conceived of "an engine that did not

require a propeller". After receiving his degree in 1935,

von Ohain became the junior assistant of Robert Wichard

Pohl, then director of the Physical Institute of the

University.

In 1936, while working for Pohl, von Ohain earned a patent

on his version of jet engines, Process and Apparatus for

Producing Airstreams for Propelling Airplanes. Unlike Frank

Whittle's design, von Ohain's engine used a centrifugal

compressor and turbine placed very close together, back to

back, with the flame cans wrapped around the outside of the

assembly. The resulting engine was even larger in diameter

than Whittle's, although much shorter along the thrust axis.

While working at the University, von Ohain often took his

sports car to be serviced at a local garage, Bartles and

Becker. Here he met an automotive engineer, Max Hahn, and

eventually arranged for him to build a model of his engine,

which cost about 1,000 DM. When it was complete he took it

to the University for testing, but ran into serious problems

with combustion stability. Often the fuel would not burn

inside the flame cans, and would instead be blown through

the turbine where it would ignite in the air, shooting

flames out the back and overheating the electric motor

powering the compressor.

In February 1936, Pohl wrote to Ernst Heinkel on behalf of

von Ohain, telling him of the design and it's possibilities.

Heinkel arranged a meeting where his engineers were able to

grill von Ohain for hours, during which he flatly stated

that the current "garage engine" would never work but there

was nothing wrong with the concept as a whole. The engineers

were convinced, and in April von Ohain and Hahn were set up

at Heinkel's works at the Marienehe airfield outside of

Rostock, Germany in Warnemünde.

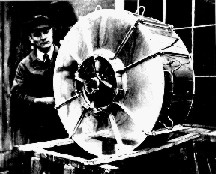

By 1935 he had developed a test engine shown with master

mechanic Max Hahn

Once moved, a study was made of

the airflow in the engine, and several improvements made

over a two month period. Much happier with the results, they

decided to produce a completely new engine incorporating all

of these changes, running on hydrogen gas. The resulting

Heinkel-Strahltriebwerk 1 (HeS 1), German for Heinkel Jet

Engine 1, was built by hand-picking some of the best

machinists in the company, much to the chagrin of the

shop-floor supervisors. Hahn, meanwhile, worked on the

combustion problem, an area he had some experience in.

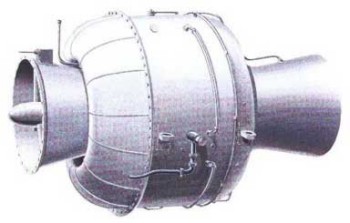

The He S-3 engine used to power the He-178 aircraft

The engine was extremely

simple, made largely of sheet metal. Construction started

late in the summer of 1936, and completed in March 1937. It

ran two weeks later on hydrogen, but the high temperature

exhaust led to considerable "burning" of the metal. The

tests were otherwise successful, and in September the

combustors were replaced and the engine was run on gasoline

for the first time. This proved to clog up the combustors,

so Hahn designed a new version based on his soldering torch,

which proved to work much better. Although the engine was

never intended to be a flight-quality design, it proved

beyond a doubt that the basic concept was workable.

While work on the HeS 1 continued, the team had already

moved on to the design of a flight-quality design, the HeS

3. The major differences were the use of machined compressor

and turbine stages, replacing the bent and folded sheet

metal, and a re-arrangement of the layout to reduce the

cross-sectional area of the engine as a whole by placing the

flame cans in an extended gap between the compressor and

turbine. The original design proved to have a turbine area

that was simply too small to work efficiently, and

increasing the size of the turbine meant the flame cans no

longer fit in the gap correctly. A new design, the HeS 3b

was proposed, which moved the flame cans out of the gap and

modified their shape to allow the widest part of the cans to

lie in front of the compressor's outer rim. In the 3b,

compressed air was piped forward to the combustion chambers,

and from there the now-hot air flowed rearward into the

turbine inlet. While not as small as the original HeS 3

design, the 3b was nevertheless fairly compact. The 3b first

ran July 1939 (some references say May), and was air-tested

under the Heinkel He 118 dive bomber prototype. The original

3b engine soon burned out, but a second one was nearing

completion at about the same time as a new test airframe,

the Heinkel He 178, which first flew on August 27, 1939, the

first jet powered aircraft to fly.

Work started immediately on larger versions, first the HeS 6

which was simply a larger HeS 3b, and then on a new design

known as the HeS 8 which once again re-arranged the overall

layout. The 8 separated the compressor and turbine,

connecting them with a long shaft, placing a single annular

combustion chamber between them, replacing the individual

flame cans. It was intended to install the engine on the

Heinkel He 280 fighter, but the airframe development

progressed much more smoothly than the engine, and had to be

used in gliding tests while work on the engine continued. A

flight-quality HeS 8 was installed in late March 1941,

followed by the first flight on 2 April. Three days later

the aircraft was demonstrated for a party of Nazi and RLM

officials, all of whom were impressed. Full development

funds soon followed.

By this point there were a number of turbojet developments

taking place in Germany. Heinkel was so impressed by the

concept that he had brought on Adolph Müller from Junkers,

who was developing an axial compressor-powered design,

renamed as the Heinkel HeS 30. Müller had left Junkers after

they purchased the Junkers Motoren company, who had their

own project underway, which by this time was known as the

Junkers Jumo 004. Meanwhile BMW was making good progress

with their own design, the BMW 003.

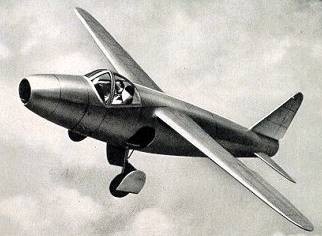

Heinkel He 178

By early 1942 the HeS 8,

officially the 109-001, was still not progressing well.

Meanwhile Müller's HeS 30, officially the 109-006, was

developing much more quickly. Both engines were still some

time from being ready for production, however, while the 003

and 004 appeared to be ready to go. In early 1942 the

director of jet development at the RLM, Helmut Schelp,

refused further funding for both designs, and ordered

Heinkel to work on a new "pet project" of his own,

eventually becoming the Heinkel HeS 011. Although this was

the first of Schelp's "Class II" engines to start working

well, production had still not started when the war ended.

Work continued on the HeS 8 for some time, but it was

eventually abandoned in the spring of 1943.

In 1947 von Ohain was brought to the United States by

Operation Paperclip and went to work for the United States

Air Force at Wright-Patterson Air Force Base. In 1956 he was

made the Director of the Air Force Aeronautical Research

Laboratory and by 1975 he was the Chief Scientist of the

Aero Propulsion Laboratory there.

During his work at Wright-Patterson, von Ohain continued his

own personal work on various topics. In the early 1960s he

did a fair amount of work on the design of gas core reactor

rockets which would retain the nuclear fuel while allowing

the working mass to be used as exhaust. The engineering

needed for this role was also used for a variety of other

"down to earth" purposes, including centrifuges and pumps.

von Ohain would later use the basic mass-flow techniques of

these designs to create a fascinating jet engine with no

moving parts, in which the airflow through the engine

created a stable vortex that acted as the compressor and

turbine.

This interest in mass-flow also led von Ohain to research

magnetohydrodynamics (MHD) for power generation, noting that

the hot gases from a coal-fired plant could be used to

extract power from their speed when exiting the combustion

chamber, remaining hot enough to then power a conventional

steam turbine. Thus a MHD generator could extract further

power from the coal, and lead to greater efficiencies.

Unfortunately this design has proven difficult to build due

to a lack of proper materials.

He also invented the idea of the "jet wing", in which air

from the compressor of a jet engine is bled off to large

"augmented" vents in the wings to provide lift for VTOL

aircraft. The concept was used in the Rockwell XVF-12

experimental aircraft, although the market interest in VTOL

aircraft was short-lived.

During his careers, von Ohain won many engineering and

management awards, including (among others) the AIAA's

Goddard Award, the US Air Force Exceptional Civilian Service

Award, Systems Command Award for Exceptional Civilian

Service, the Eugene M. Zuckert Management Award, the Air

Force Special Achievement Award, and just before he retired,

the Citation of Honor. In 1991 von Ohain and Whittle were

jointly awarded the Charles Stark Draper Prize for their

work on turbojet engines.

He retired from Wright-Patterson in 1979 and took up an

associate professor position at the nearby University of

Dayton. He later moved to Melborne, Florida with his wife

Hanny, where he died in 1998. He is survived by four

children.

|